-

- Home

- Sustainability

- Electric Arc Furnace

Electric Arc Furnace

Positioning New Zealand as a global leader in low-emissions steel production.

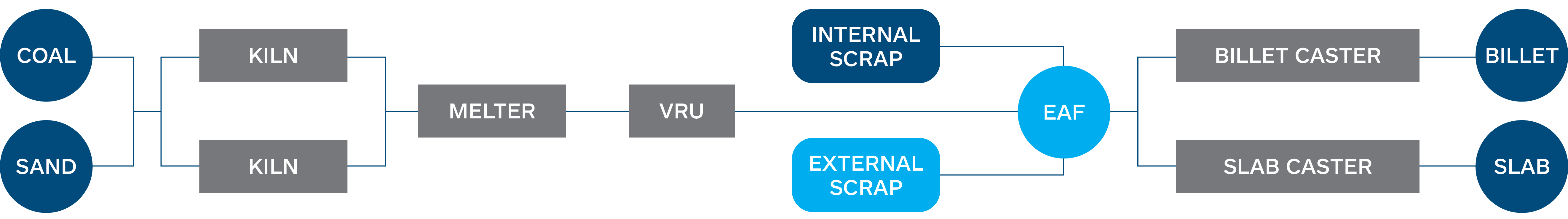

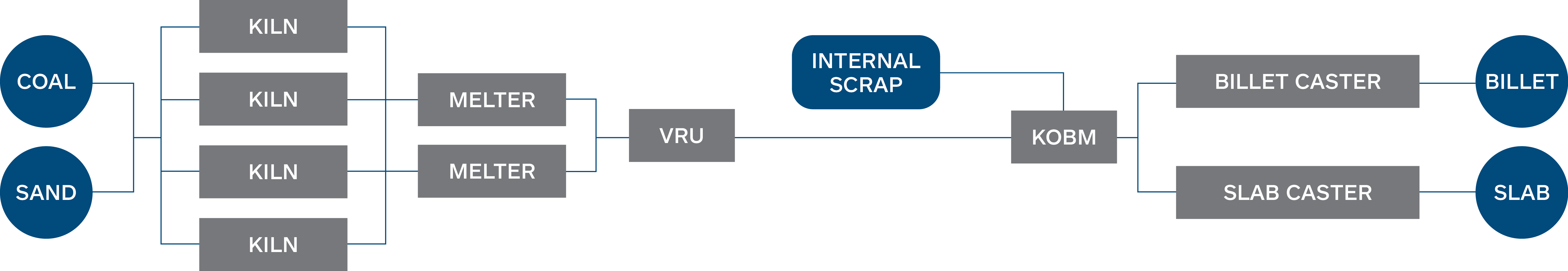

New Zealand Steel’s Electric Arc Furnace (EAF) has received approval and is set for operation in 2026. The EAF will enable New Zealand Steel to shrink its carbon footprint and help New Zealand, as a nation, be as close to self-sufficient as possible, using renewable energy and recycling scrap steel. This project underscores Pacific Steel’s own commitment to a circular economy model, with all our feed material being supplied by New Zealand Steel.

In a landmark partnership between New Zealand Steel and the Government, the EAF project at Glenbrook, South of Auckland, replaces the current oxygen steelmaking furnace and two coal-fueled kilns, achieving a substantial cut in coal use and carbon emissions. Using an average of 30 megawatts on New Zealand’s largely renewable grid, the EAF will melt down steel scrap, previously exported offshore, and process it into prime steel for new products. This initiative will provide our customers with lower carbon steel products, helping them build a stronger and more sustainable New Zealand.

Example of an electric arc furnace in action.

The EAF project exemplifies the benefits of a local circular economy model for both our industry and country. It enables us as a nation to solidify the circularity of steel, with the EAF allowing the recycling and manufacturing of steel within New Zealand in a continuous loop. The introduction of a local EAF also creates the largest industrial decarbonisation effort in our country’s history. Join us on this momentous journey as we forge a path to locally made, low carbon steel.

Download our brochure to learn more about our EAF journey.